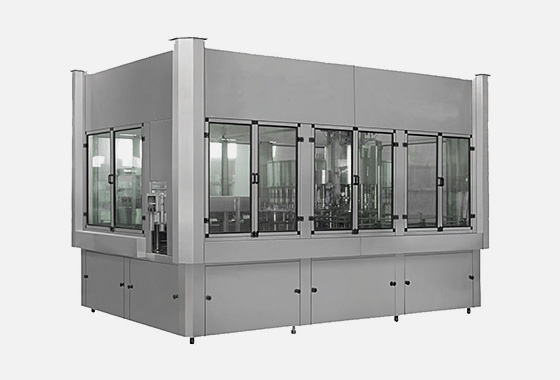

Product Description

The CGF PET bottle three in one machine integrates washing, filling, and capping, and is developed based on advanced foreign technology according to the filling process requirements of pure water and other beverages.

1. Work process:

The bottles are transmitted through the air duct and then transmitted to the bottle washing machine of the three in one machine through the bottle shifting star wheel. The rotary table of the bottle washing machine is equipped with a bottle clamp, which clamps the bottle mouth and flips it 180 ° along a guide rail to make the bottle mouth downward. In a specific area of the bottle washing machine, the nozzle of the bottle washing clamp sprays bottle washing water to rinse the inner wall of the bottle. After washing and draining the bottle, flip it 180 ° along the guide rail under the bottle clamp to make the bottle mouth upward. The cleaned bottles are exported from the bottle washing machine and transported to the filling machine through the bottle pulling star wheel. The bottle entering the filling machine is stuck by the bottleneck support plate and lifted by the cam, then the filling valve is pushed open by the bottle mouth. Gravity filling method is used for filling. After the filling valve is opened, the material completes the filling process through the filling valve. After the filling is completed, the bottle mouth descends and leaves the filling valve, and the bottle enters the capping machine through the transition wheel of the bottleneck. The anti rotation knife on the capping machine catches the bottleneck area, keeping the bottle upright and preventing rotation. The capping head maintains revolution and rotation on the capping machine, and under the action of the cam, it achieves the actions of grabbing, covering, rotating, and uncovering, completing the entire capping process. The finished bottles are transported from the capping machine to the bottle delivery chain through the bottle delivery wheel, and then transported out of the three in one machine through the delivery chain.

2. Main features:

(1) The machine has a compact structure, complete control system, convenient operation, and high degree of automation;

(2) Changing the bottle shape only requires replacing the rotating cap part of the star wheel and the curved guide plate to achieve;

(3) The parts in contact with the materials are all made of high-quality stainless steel, with no dead corners and easy to clean;

(4) Adopting a high-speed filling valve, the liquid level is accurate without liquid loss, ensuring the filling process requirements;

(5) The sealing head adopts a magnetic constant torque device to ensure the sealing quality and not damage the bottle cap;

(6) Adopting an efficient capping system with complete automatic control and protection devices;

(7) Equipped with a comprehensive overload protection device, it can effectively protect the safety of equipment and operators;

(8) The control system has functions such as production speed control, cap shortage detection, automatic stop of stuck bottles, and output counting;

(9) The main electrical components and pneumatic components are all world renowned products;

(10) The operation of the entire machine adopts advanced touch screen control, which can achieve human-machine dialogue operation.

3. Declaration:

Our company has the right to modify products without prior notice.

Technical parameters (example)

|

型 號

|

CGF50-50-12

|

|

工位數

|

洗瓶50,灌裝50,封蓋12

|

|

生產能力

|

20000瓶/小時(500ml/瓶)

|

|

氣源壓力

|

0.7 MPa

|

|

耗氣量

|

1 m3/min

|

|

沖瓶水壓力

|

0.2-0.25 MPa

|

|

沖瓶水耗量

|

3 噸/小時

|

|

主電機功率

|

7.5 KW

|

|

整機功率

|

10 KW

|

|

外形尺寸

|

4800x3600x2600(長×寬×高)

|

|

整機重量

|

9000 kg

|

Note: In addition to the specifications of the table series, it can also be designed separately according to customer requirements.