Food, Pharmaceutical, Bioengineering

086-21-34711610

- Home

-

Products

- ◆ Vacuum Frying

- Experimental automatic vacuum fryer

- JS-10 Automatic Vacuum Frying Machine

- JS-25 automatic vacuum fryer

- JS-50 automatic vacuum fryer

- JS-100 automatic vacuum fryer

- JS-300 automatic vacuum fryer

- JS-400 automatic vacuum fryer

- JS-500 automatic vacuum fryer

- ◆ Fruit、 Vegetable

- tomato paste production line

- Carrot fruit and vegetable processing production line

- Apple/pear fruit processing production line

- Jujube/hawthorn fruit processing production line

- Tomato sauce packaging production line

- Mango/pineapple fruit processing production line

- Peach/apricot/plum fruit processing production line

- Orange/citrus fruit processing production line

- ◆ Dairy、Beverage

- Milk powder processing production line

- Beverage processing production line

- Pasteur milk processing production line

- UHT milk processing production line

- Yogurt processing production line

- Fruit juice and tea beverage processing production line

- Plant protein beverage processing production line

- Cheese processing production line

- ◆ Biopharmaceutical

- Raw material drug processing production line

- Honey processing production line

- Milk powder processing production line

- Bone Soup Processing Production Line

- Bone element processing production line

- ◆ Single Device

- Fruit and vegetable processing equipment

- Stainless steel container equipment

- Concentration, flash, and degassing equipment

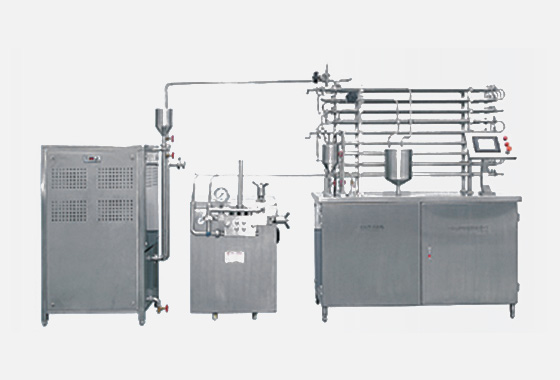

- Sterilization equipment

- Homogenization and emulsification equipment

- Filtration, water treatment

- CIP cleaning equipment

- Spray drying equipment

- Filling equipment

- Pharmaceutical equipment

- Cases

- Service

- News

- About Us

- Contact Us